Inspection Productivity improves with ALL NEW work holding and fixture plates!

As QC Inspectors you may be measured on contributions you make to improve your inspection process. Be the first to introduce this brand new line of inspection work holding designed with “lean” principles in mind.

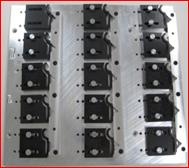

Offered by a local manufacturer, The Pitbull Clamp Co., Inc. of Boylston, MA, this new line designed for both

traditional CMMs and

Vision Systems includes unique spring blocks, hold downs, stand-offs, stops, rails, and plates. These products are the most cost-effective on the market today, not only because of their low price, but because they are simple, versatile, and

improve productivity. Easily design them into  custom multiple-part fixtures or use them on a fixture plate for 1-piece inspections.

custom multiple-part fixtures or use them on a fixture plate for 1-piece inspections.

Designed for leaner inspection!

- One-handed part swaps with a squeeze of a trigger.

- “Fixture Up” economically.

- No tools or tape needed – no more messy surfaces.

- High quality, durable, non-marring & proudly made in the USA!

- Low-profile, simple designs stay out of your way.

- Standard kits and plates available – or customize.

- Use on VISION and probe CMMs.

- Arrives in FREE 5S-Ready storage solution.

Productivity improvements are achieved by the unique design – the gripping edge of the Trigger-Block™, Cross-Bow™ and Trigger-Finger™, and D-Block™ works like a trigger or spring to secure and release your work. Parts are held with plenty of force for measuring and with a squeeze of the trigger a part can be quickly released and replaced. Part change-over is one-handed with no need for tools and tape.

This new inspection work holding exemplifies lean concepts by reducing non-value added time and increasing productivity and profits… and a “lean” solution isn’t “lean” unless it’s economical.

“This innovative inspection work holding puts a unique perspective on how products can assist a company to sustain Lean. The clamps especially help to reduce the time taken for the non-value-added service of inspection… in an economical way. Just like Lean – it helps a company to reduce some of the non-value added waste that affects profits.” Kevin Smith, Project Manager, Massachusetts Manufacturers Extension Partnership (MassMEP)

You may want to “fixture-up” for inspecting high quantity, repeat jobs. This clamping solution is affordable enough to shelf with your fixtures. This is a common “lean” technique in machining and can now be accomplished in your inspection departments. Medical parts manufacturers like Hologic, Inc. reap the benefits.

You may want to “fixture-up” for inspecting high quantity, repeat jobs. This clamping solution is affordable enough to shelf with your fixtures. This is a common “lean” technique in machining and can now be accomplished in your inspection departments. Medical parts manufacturers like Hologic, Inc. reap the benefits.

“The quality of the products that you provide us is impeccable. CMM inspection of large part lots is now much faster and more economical.” Wayne Loomer, Quality Manager, Hologic, Inc., Marlborough, MA

Moving parts through inspection faster not only reduces the cost to inspect, but influences the productivity earlier in the manufacturing process. High production shops can produce a lot of junk, fast while accumulating parts wait to be inspected. Or, they implement ways to speed up inspection by finding innovative ways to make process improvements.

Increase the value, productivity, and reinforce the intelligence of your inspection machines! Learn more or order at www.leaninspection.com.

Patents Pending, Products of The Pitbull Clamp Co., Inc., 141 Shrewsbury Street, Boylston, MA 01505 – 508-869-0373