Revolutionizing Manufacturing with Virtual Data Rooms: A Key to Accelerated Growth

A Fresh View Of the Data Rooms for the Manufacturing Companies

A few decades ago, the physical data rooms were the only solution for the manufacturers. The images, audio, and videotapes have to be stored physically. Yet in today’s highly intensive competition, the VDR technological integration improves the company’s efficiency.

A virtual data room (or VDR) in the manufacturing innovation that provides the cloud-based working space for the company. In essence, the virtual data rooms allow achieving restricted access to the information for collaboration, viewing, editing, and using the information or files.

The Digital Shift in Manufacturing

Nowadays, it’s impossible to imagine the effective data management of documents, audio, and video files between the supplier and manufacturer without the proper digital transformation.

That’s why, the basic premise of the transformation in the manufacturing sector is the growing necessity to improve supplier-manufacturer exchange and business relationships via secured and reliable VDR solutions.

Understanding Virtual Data Rooms

Although, depending on the vendor, there are differences in the virtual data room features, some of them are universal for the VDRs. These universal features are:

-

Cloud-based storage of the text, image, audio, and video files;

-

Sharing with the data across the authorized company’s staff;

-

Project management for tracking the processes;

-

Collaboration enhancement through restricted access to the files;

-

Secure data storage via a two-step authentication procedure.

However, there’s always the option of the customization for the VDR’s features, depending on the industry.

Benefits of Virtual Data Rooms in Manufacturing

The VDR operational efficiency is one of the main benefits of the solution. However, there are other kinds of benefits that CEOs are constantly looking for:

-

Supply chain management provides the viewing of supplier’s contracts, orders, records, and EHS documents;

-

Global partnerships through managing the supplier’s documentation. The access to the intellectual property security related to purchase orders, invoices, etc.;

-

The production process management includes the production schedules, quality control reports, production charts, other kinds of production-related information, etc.;

-

Distribution process management provides with the info like shipping, location, distribution, and information updates;

-

Quality control includes info on agreements, product features, equipment records, validation, etc.

These benefits collectively contribute to enhancing overall organizational effectiveness and competitiveness.

Implementing Virtual Data Rooms for Manufacturing Growth

The first goal of the implementation strategies through the shift from the physical to the virtual data rooms is to increase the staff’s productivity. For this purpose, the solution for the manufacturing company must stand on the grounds such as:

-

System integration must provide a short staff training curve;

-

The secured platform must provide instant access to the information;

-

The VDR must solve the company’s goals;

For more details, check this article on the pros and cons of the VDRs.

Case Studies in Manufacturing

Manufacturing companies benefit tremendously when moving to virtual data rooms, and there are plenty of industry examples of this. The case in point is the Acme corporation which has used the VDR as a tool to increase competitiveness by sharing the info with the suppliers such as financial information, business plans, product demos, etc.

The positive of the technology impact resulted in an increase in the information exchange between the company and suppliers and a better position in the market. And each day, there are more success stories come up because of the proper implementation of the VDR.

Conclusion

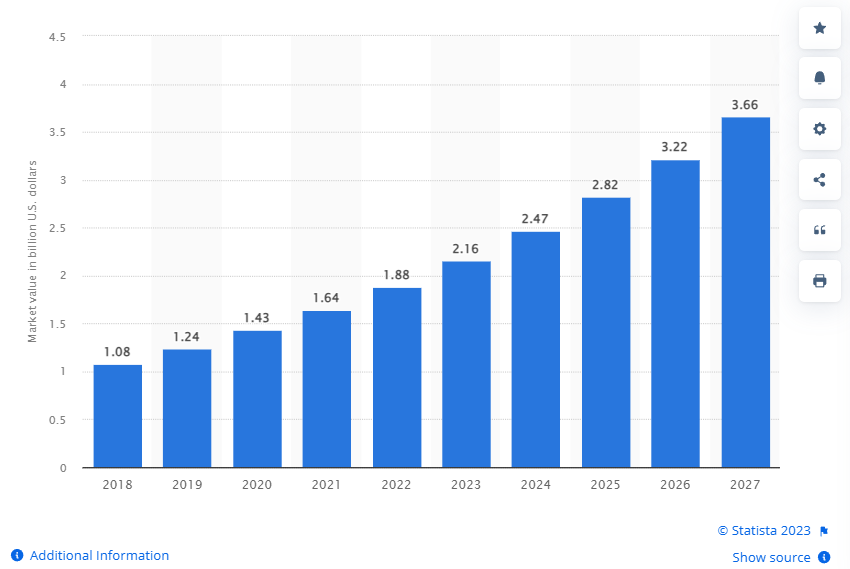

The future of manufacturing industry connected to the rapid shift to VDR technology. In terms of launching, maintaining, and updating, the VDR is drastically more cost-effective than the physical data rooms. Because of the competitive advantage that provides the VDR and a set of the digital tools, the VDR market anticipated to grow in the years ahead.